Formula 1 is the most watched annual sporting series in the world; with more than 525 million people watching over the course of a season; an estimated turnover of more than £3 billion GBP - it embodies the cutting edge of technology in the automotive industry. With SEP’s ‘Cleanroom’ manufacturing, climate controlled rubber compound storage and post cure ovens with traceable data logging, we have the knowledge and experience with our Technical Team and In-House tooling department to fulfil customer requirements on demand, on time, to the highest standard.

Rubber Moulded Seals & Components

'Cleanroom'

manufacturing, climate controlled rubber compound

storage, post cure ovens with traceable data

logging; SEP meets all expected criteria. From 3D

modelling and tool design to finished component

inspection on the most advanced multi sensor

inspection machines guarantee expected quality and

finish from ALL rubber types. Rubber to metal

bonding is a speciality.

Click here to read more

Static & Inflatable Rubber Extruded Profile

Seals

Please take time to

visit us and witness the most capable UK based

designer and manufacturer of Extruded Profiled

& Inflatable Seals; offering high & low

temperature resistance with all specification

grades in Silicone, Fluorosilicone, EPDM, Neoprene,

Nitrile, HNBR and Viton. Our unique tool design can

produce seals with straight joins in endless seals

to mitered or fully moulded corners, combined with

our life cycle seal fatigue testing ensures our

seals always meet customer expectation.

Click

here to read more

Precision Soft Cut Gaskets

SEP boast the

highest specification CNC Gasket Cutting operation

in the UK; two Atom Flashcut oscillating knife with

multi-zone vacuum cutting beds and a state of the

art Waterjet with micro head cutting technology.

The three machines give SEP the versatility to cut

any material to the best finish and finest

tolerances, combined with a 3M x 2M cutting area,

no job is too big or too small. We offer parts cut

from our own specification moulded sheet rubber to

recognised jointing brands such as Klinger and

Flexitallic. Cutting laminates is a speciality of

SEP with the new Waterjet micro head

technology.

Click

here to read more

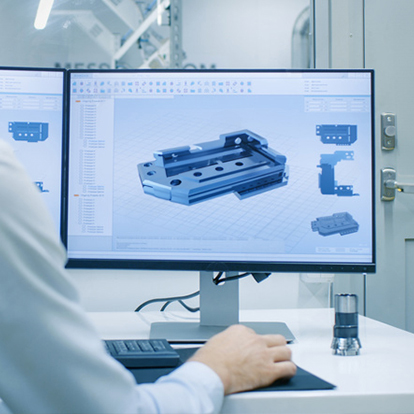

Precision Machined Components

Please see our

Latest News page for progress reports.

During 2014 SEP is investing heavily in a brand new

clean room machining environment, incorporating the

latest 5 axis machining; all programmed from our

SolidWorks Professional 2015, 3D modelling

software.

Our investment plans will also incorporate a 5 axis

programmable CMM; capable of hands free inspection

to First Article standards.

Click

here to read more

Services & Products

Select the relevant service / product below to read

more and find out more information.